When choosing hoses for domestic or industrial use, it is important to consider not only their diameter and length, but also the material. The most common options are rubber hoses and stainless steel hoses. Which of these options should you prefer: the strength of stainless steel or the flexibility of rubber?

When choosing hoses for domestic or industrial use, it is important to consider not only their diameter and length, but also the material. The most common options are rubber hoses and stainless steel hoses. Which of these options should you prefer: the strength of stainless steel or the flexibility of rubber?

Both materials have their own unique advantages and disadvantages, making them ideal for different applications. This article will help you understand the key differences, pros and cons of stainless steel and rubber hoses so that you can make a clear determination.

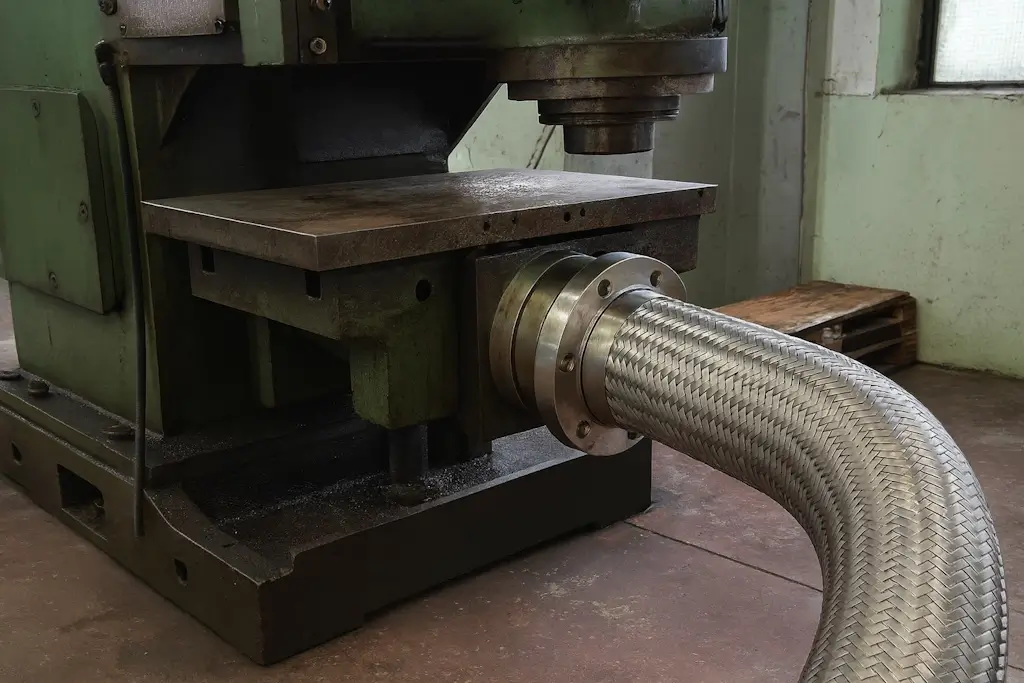

Stainless Steel Hoses: Strength and Durability

Stainless steel hoses have a corrugated structure that can be protected by additional braiding. They are known for their exceptional strength and resistance to extreme conditions.

Pros:

- High temperature resistance: Stainless steel can withstand significantly higher and lower temperatures than rubber. This makes it an ideal choice for transporting hot liquids, steam or for working in extreme cold conditions.

- Resistance to pressure and water hammer: The metal construction provides high resistance to sudden pressure drops, which is critical for water supply systems and industrial equipment.

- Durability and corrosion resistance: Stainless steel does not rust, does not crack over time and is not exposed to ultraviolet light. The service life of such hoses can reach 10 years or more.

- Hygiene: The smooth inner surface does not contribute to the growth of bacteria, which is important for the food industry and the connection of household appliances.

- Protection against mechanical damage: The outer braid, as in Eco-Flex Gas EN14800 hose, reliably protects the hose from kinks, breaks and external influences.

Cons:

- Less flexibility: Compared to rubber counterparts, metal hoses are more rigid. Although they can be bent, their bending radius is limited.

- Higher cost: The quality and durability of stainless steel are reflected in its price, which is usually higher than that of rubber hoses.

- Risks of incorrect installation: Poor installation or excessive twisting can damage the corrugated structure.

Application areas: connection of mixers, boilers, heating and fire sprinkler systems, gas equipment, food and chemical industries.

Rubber Hoses: Flexibility and Versatility

Rubber hoses are a traditional and widely used option due to their elasticity and affordability. They are often reinforced with textile or metal reinforcement for added strength.

Pros:

- High flexibility and elasticity: Rubber bends easily in any direction, making these hoses ideal for use in hard-to-reach places and for moving connections.

- Affordable price: Rubber hoses are usually much cheaper than their metal counterparts, making them a popular choice for household needs, such as watering.

- Good vibration absorption: The elasticity of rubber allows it to effectively dampen vibrations from operating equipment.

- Easy installation: Due to its flexibility, they are easy to connect without the risk of damage.

Cons:

- Less durability: Rubber is prone to aging, cracking under the influence of sunlight, temperature changes and contact with some chemicals.

- Limited resistance to pressure and temperature: Most rubber hoses are not designed for high pressure and extreme temperatures, although there are reinforced models for more difficult conditions.

- Tendency to kinks: Without proper reinforcement, rubber hoses can kink, which limits the flow of fluid.

- Health risk (in cheap models): Poor-quality technical rubber can emit harmful substances and have an unpleasant odor, making it unsuitable for drinking water.

Areas of application: watering gardens and vegetable gardens, high-pressure washing, automotive industry (fuel, brake systems), transportation of air, technical water, some chemical solutions.

Comparison Table

| Features | Stainless Steel Hose | Rubber Hose |

|---|---|---|

| Durability | ⭐⭐⭐⭐⭐ (High) | ⭐⭐ (Low-Medium) |

| Flexibility | ⭐⭐ (Limited) | ⭐⭐⭐⭐ (High) |

| Heat Resistance | ⭐⭐⭐⭐⭐ (High) | ⭐⭐ (Limited) |

| Pressure Resistance | ⭐⭐⭐⭐⭐ (High) | ⭐⭐ (Low-Medium) |

| Cost | 💰💰💰 (Medium-High) | 💰 (Low) |

| UV Resistance | ✅ Yes | ❌ No |

| Main Advantage | Reliability and durability | Flexibility and price |

Conclusion

The choice between stainless steel hose and rubber hose directly depends on your needs and operating conditions.

Choose stainless steel if you need a durable and reliable solution for critical connections operating under high pressure or extreme temperatures. This is an investment in safety and peace of mind for many years, especially for stationary equipment.

Prefer rubber hose if flexibility, mobility and low cost are your priorities. It will be an excellent choice for watering or other tasks where high pressure and temperature resistance is not required, and the hose is often moved.

Ultimately, the right choice is a balance between price, operating conditions and the required level of reliability.

At Eco-Flex you will find a large selection of stainless steel hoses, as well as all the necessary accessories for a reliable connection. Contact us – we will help you choose the best option for any task!