Stainless steel metal hoses are a reliable solution for solving many problems. Due to their high strength and flexibility, corrugated stainless steel pipes combine protection against mechanical damage and ease of installation even in hard-to-reach places.

Corrugated stainless steel metal hoses – purpose

Our corrugated metal hoses are used for:

- transportation of various gases, liquids and bulk materials;

- use in ventilation, heating and water supply systems;

- laying and protecting electrical cables;

- installation in industrial and domestic networks.

Main advantages of corrugated metal pipes

Strength and durability: stainless steel has high strength and corrosion resistance, which makes metal hoses durable and reliable.

- Flexibility: our metal corrugated pipe can be bent without damage, which makes it easy to lay in complex configurations.

- High temperature resistance: stainless steel metal hoses can operate at high temperatures.

- Fire resistance: stainless steel has high fire resistance, so Eco-Flex metal hoses are safe for use in environments with open fire sources.

- Chemical resistance: stainless steel metal hoses are suitable for use in chemically aggressive environments, as this material has high resistance to chemical reagents.

- Versatility: suitable for industrial and domestic use.

- Hygiene: stainless steel is a hygienic material that does not change the odors and taste of products. Thanks to this, Eco-Flex metal hoses can transport drinking water and various food products.

Features of stainless steel metal hoses

On our equipment, we produce flexible metal hoses with diameters of 8 mm, 12 mm, 16 mm, 20 mm, 25 mm and 32 mm. Their purpose can be different:

- metal hoses 8 mm and 12 mm are most often used for transporting liquids and gases;

- metal hoses 16 mm and 20 mm are a universal solution for most tasks;

- metal hose 25 mm is optimal for medium loads;

- metal hose 32 mm is the choice for powerful communications.

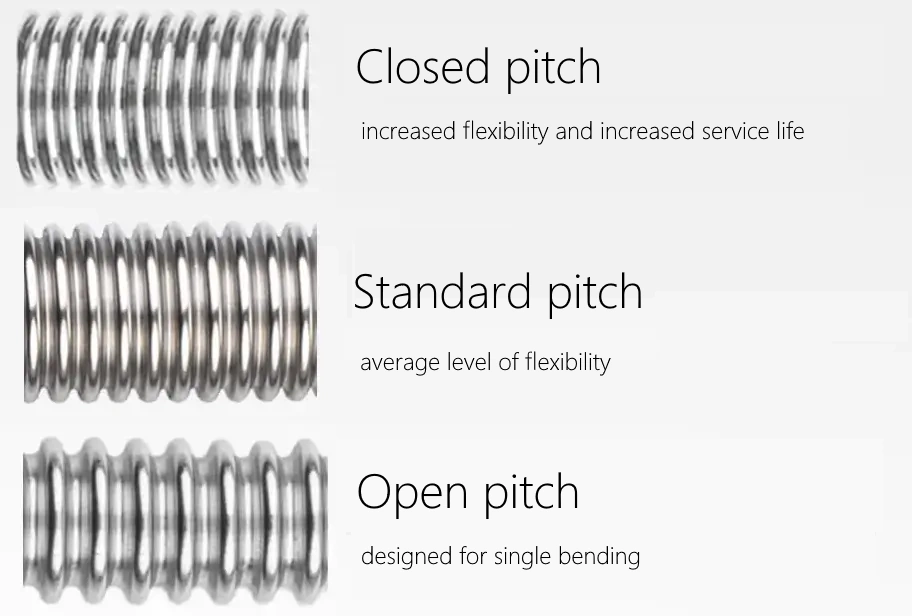

Also, our corrugated stainless steel pipes can have different corrugation pitches.

What does the corrugation pitch of metal hoses affect?

The corrugation pitch determines the distance between the corrugations on the surface of the hose, which directly affects the flexibility of the product.

With a closed pitch, this distance is smaller than for hoses with a standard corrugation pitch, which gives additional flexibility to the metal hose. Metal hoses with an open and standard corrugation pitch can have a stainless steel braid to prevent excessive stretching when working under high pressure.

The materials used for the production of metal hoses are stainless steel grades AISI 304, AISI 304L and AISI 316L.

Metal hose marking

The article number of Eco-Flex metal hoses contains 3 digits separated by a dot and an alphanumeric designation.

The first 2 digits before the dot indicate the corrugation pitch:

- 01 – closed;

- 02 – standard;

- 03 – open.

The digit after the dot indicates the presence of braiding:

- 0 – no braiding;

- 1 – braiding.

The alphanumeric designation determines the nominal diameter of the metal hose in millimeters, for example DN12 – the nominal diameter of the metal hose is 12 mm.

Technical characteristics

| Article | Corrugation pitch | DN | Connection | Pressure at 20° C, bar |

|---|---|---|---|---|

| 01.0 DN12 | Closed | 12 | 1/2″ | 7 |

| 01.1 DN12 | Closed | 12 | 1/2″ | 40 |

| 02.0 DN12 | Standard | 12 | 1/2″ | 8 |

| 02.1 DN12 | Standard | 12 | 1/2″ | 95 |

| 02.0 DN16 | Standard | 16 | 3/4″ | 8 |

| 02.1 DN16 | Standard | 16 | 3/4″ | 90 |

| 02.0 DN20 | Standard | 20 | 1″ | 4 |

| 02.1 DN20 | Standard | 20 | 1″ | 70 |

| 02.0 DN25 | Standard | 25 | 1 1/4″ | 2,7 |

| 02.1 DN25 | Standard | 25 | 1 1/4″ | 60 |

| 02.0 DN32 | Standard | 32 | 1 1/2″ | 3 |

| 03.0 DN8 | Open | 8 | 1/4″ | 16 |

| 03.0 DN12 | Open | 12 | 1/2″ | 16 |

| 03.0 DN16 | Open | 16 | 3/4″ | 16 |

| 03.0 DN20 | Open | 20 | 1″ | 10 |

| 03.0 DN25 | Open | 25 | 1 1/4″ | 8 |

| 03.0 DN25 0.3 mm | Open | 25 | 1 1/4″ | 12 |

| 03.0 DN32 | Open | 32 | 1 1/2″ | 4 |

| 03.0 DN32 0.3 mm | Open | 32 | 1 1/2″ | 10 |