In the world of plumbing, construction and industry, terms may seem interchangeable at first glance, but in fact have clear differences in design, purpose and application.

In the world of plumbing, construction and industry, terms may seem interchangeable at first glance, but in fact have clear differences in design, purpose and application.

Let’s consider two common concepts: corrugated pipe and flexible hose to avoid confusion and make the right choice for your needs. Given the wide variety of these products, the main attention will be paid to stainless steel products.

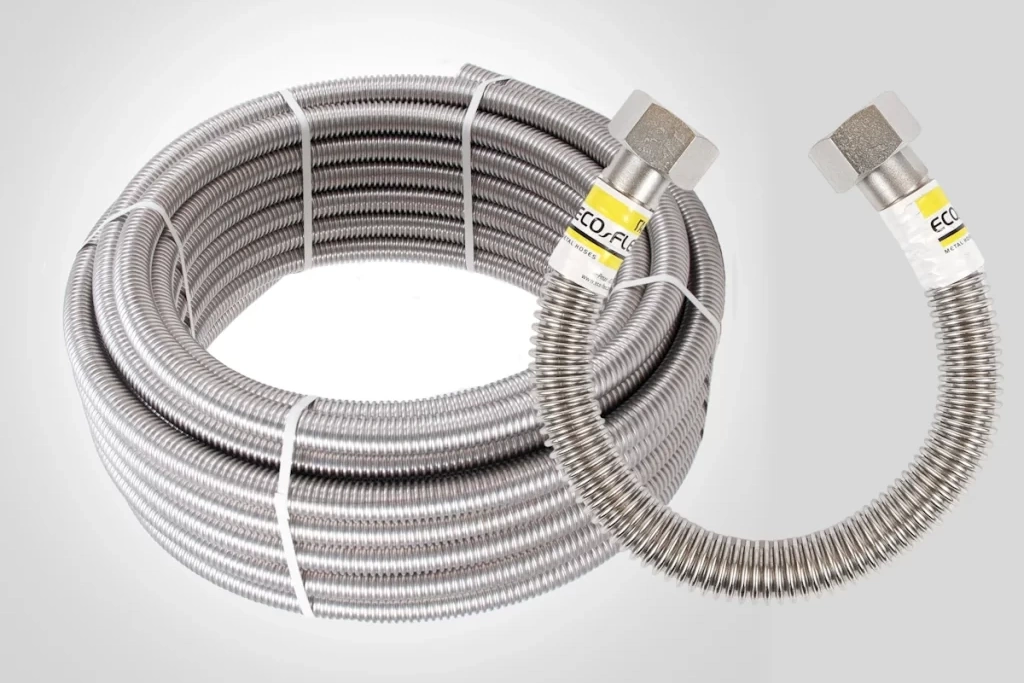

Corrugated stainless steel pipe

A corrugated pipe (or corrugation) is a pipe that has a wavy surface. This feature gives it significant flexibility and resistance to deformation.

Design

The main difference between corrugated pipes is the presence of corrugations (waves) along the entire length. Depending on the purpose, they may have additional layers to increase strength or insulation (for example, additional coating or braiding). Another feature is that a stainless steel corrugated pipe does not have threaded ends (fittings). It is the “heart” of many products that connect various equipment. An example of such a product is stainless steel metal pipe, on the basis of which hoses and other products can be manufactured.

Characteristics of corrugated pipes

- Flexibility: some corrugated pipes are very flexible, others are more rigid. This depends on the corrugation pitch and affects the pressure level. More rigid products can “remember” the shape of the bend.

- Resistance to extreme temperatures: stainless steel is a material with high temperature resistance, and therefore the metal hose can withstand very high or low temperatures.

- Resistance to pressure drops: the presence of corrugations “smoothes” the effect of water hammer or sudden pressure drops when pumping gases.

- Resistance to corrosion and aggressive substances: corrugated stainless steel pipes are not afraid of rust and the effects of most chemically active substances.

- Durability: even under harsh operating conditions, a corrugated stainless steel pipe can last for many years.

Applications

- Plumbing: water supply, connection of some devices.

- Industry: pumping of various liquids, gases, bulk materials.

- Heating systems: manufacturing heat exchangers based on metal pipes, connecting heat pumps, underfloor heating.

- Energy and ecology: corrugated stainless steel pipe can be used for exhaust gas removal from generator equipment, as well as connecting solar systems.

- Electrical installation: protecting electrical cables from mechanical damage, moisture and dust.

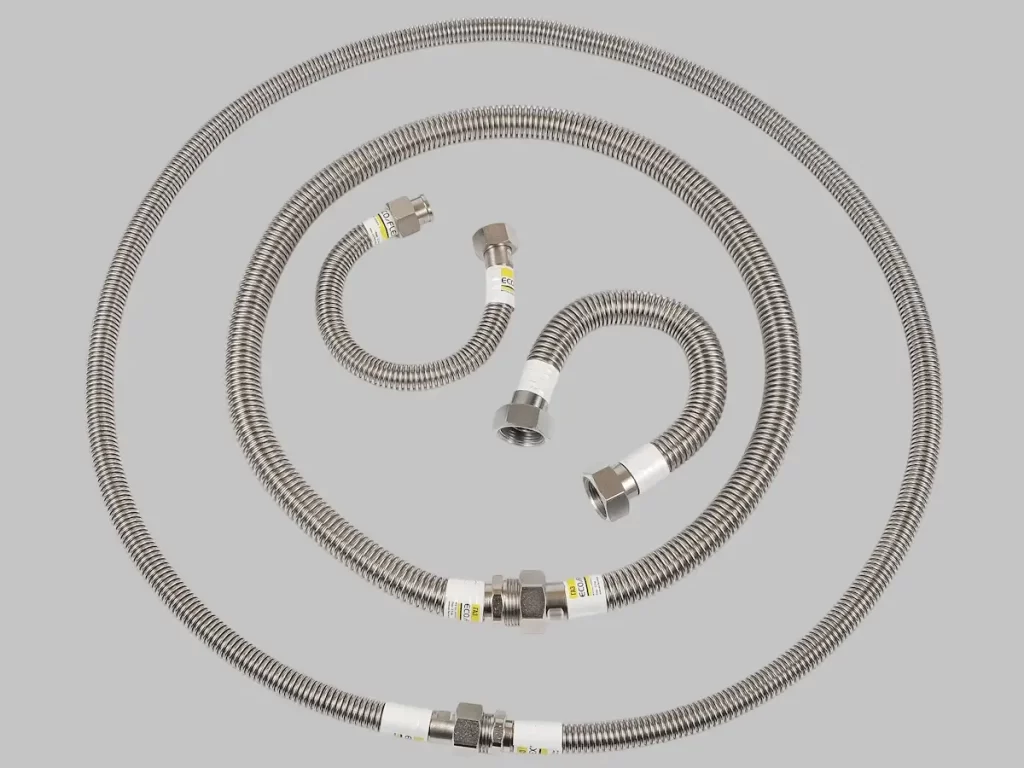

Stainless steel flexible hose

A flexible hoses is a finished product designed to connect plumbing fixtures to water supply or heating systems, as well as gas appliances to gas distribution networks. Metal flexible hoses are made on the basis of corrugated pipes. The presence of corrugations makes it possible to bend a stainless steel product without special equipment.

Design

Unlike corrugated pipes, flexible hoses are always finished products, they are, they are equipped with special fittings (nuts, joints) for quick and reliable connection. Some models may have additional insulation to reduce heat loss when connected to a hot water or heating system (for example, Eco-Flex Water Heat Hose), others – additional PVC coating or braiding (like Eco-Flex Gas EN14800 gas hose).

Characteristics of flexible stainless steel hose

- Large choice: the presence of a large number of flexible hoses with different types of connections and lengths allows you to connect devices located at any distance from the connection points and having a variety of connections.

- Flexibility: easily bent, while maintaining the passage diameter and remembering the shape of the bend.

- Pressure resistance: the ability to withstand significant pressure of liquid or gas.

- Resistance to temperature changes: especially important for connecting hot water.

- Ease of installation: Owing to ready-made fittings, installation and connection can be made even by a person with initial skills and knowledge.

Application

- Connecting faucets to water pipes.

- Connection of toilets and bidets, boilers and water heaters.

- Connection of convectors and heating radiators.

- Connection of gas stoves, columns, boilers to gas distribution networks.

Conclusion

Each of the elements described above has its own scope and design features. Corrugated pipe is used for stationary and technically complex solutions, and a flexible hose is a universal, inexpensive and easy-to-install option for various gas and plumbing connections. Knowing these differences will help you make the right choice when repairing or installing engineering systems.