When choosing a water hose, it is important to consider not only the material and length, but also the diameter. It is the diameter that determines the throughput, pressure stability and ease of operation in a particular system. Eco-Flex offers flexible water hoses of various diameters, which are ideal for both domestic and industrial needs.

When choosing a water hose, it is important to consider not only the material and length, but also the diameter. It is the diameter that determines the throughput, pressure stability and ease of operation in a particular system. Eco-Flex offers flexible water hoses of various diameters, which are ideal for both domestic and industrial needs.

The correct choice of hose diameter is key to the efficient and safe operation of water supply systems, irrigation, household appliances or industrial equipment. The diameter determines the water pressure, flow rate, ease of installation and compatibility with fittings. An incorrectly selected diameter of the flexible supply can lead to a decrease in pressure or even damage to the equipment. In this article, we will consider the most common diameters of flexible water hoses and their optimal areas of application.

Geometric parameters of water hoses

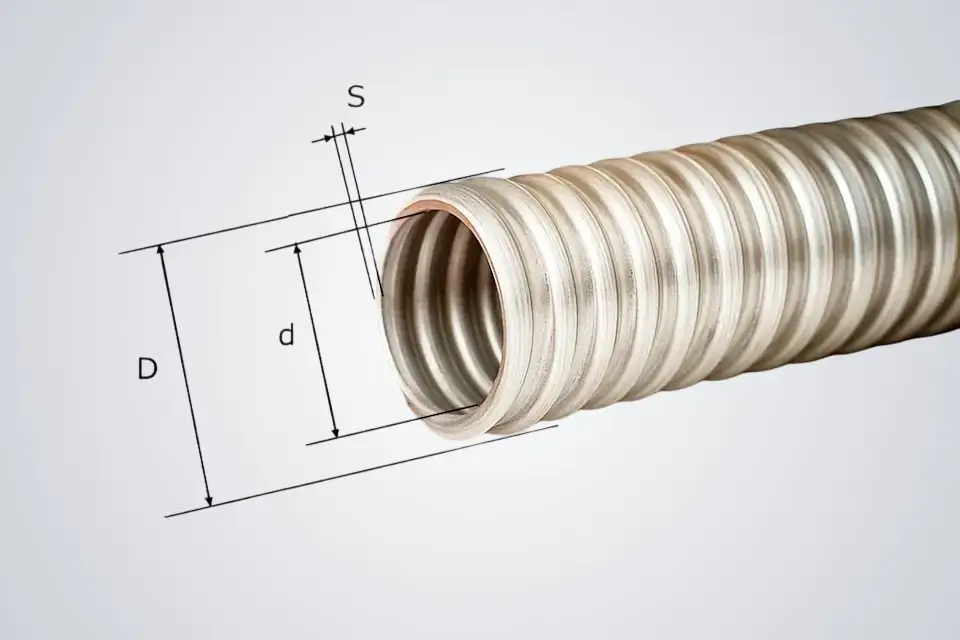

The main geometric characteristics of flexible hoses are the inner and outer diameters of the hose, as well as the wall thickness.

- Inner diameter. This is the diameter of the hole in the hose through which liquid or gas passes. This parameter is key when choosing a flexible hose for certain tasks, as it determines the throughput. The inner diameter is often denoted as DN – the so-called nominal diameter.

- Outer diameter. This is the total diameter of the hose, including its walls. This parameter is important for selecting fittings and for understanding how much space the hose will take up. It is this size that will be discussed in the article.

- Wall thickness. This is the distance between the inner and outer surfaces of the hose. The wall thickness affects the strength of the product, its flexibility, resistance to pressure and external damage.

Connection between hose diameters, threaded end and connection

Usually, stainless steel hoses are equipped with threaded ends (nut or fitting), which are either crimped around the body of the metal hose or welded to it.

Ideally, the diameter of the hose should coincide with the diameters of the threaded end and connection – then there will be no sharp drops in pressure and water flow rate in the system. However, for many objects there are different requirements for the types and diameters of connections, and it is not always possible to ensure a perfect match of sizes. Of course, no one will install a 1/2” inch nut or fitting on a flexible hose – the hose will be equipped with a 1/2” diameter end.

For example, to connect a faucet, you need a hose with a half-inch thread (DN12, for connection to the water supply system) on one end and a metric thread (M10 or M8, for connecting the faucet) on the other. The drop in cross-sectional area at the hose outlet is quite noticeable, but it will not work to connect in another way.

And this is far from an isolated case. The reason for this is different standards in different countries, different requirements for different plumbing devices. In some cases, it is advisable to use adapters from one diameter to another.

General principles for choosing the diameter of water hoses

When choosing the diameter of the hose, there are several factors to consider:

- Pressure and flow: Check the maximum working pressure that the hose can withstand. This is important to prevent damage of it. The larger the inner diameter of the hose, the more water it can pass per unit of time at the same pressure. However, if the pressure in the system is low, too large a diameter can lead to a scattered and weak stream.

- Hose length: Choose a hose of such a length that it reaches all the necessary areas without excessive tension. For longer hoses, it is recommended to choose a larger diameter to compensate for pressure losses due to friction resistance. However, a hose that is too long can lead to a pressure drop.

- Purpose: Different tasks require different volumes of water, which determines the required diameter of the hose.

Common hose diameters for connecting household appliances and plumbing

For flexible water supply to household appliances and plumbing, hoses are used taking into account the required throughput:

- 3/8″ (8-10 mm): Used to connect some models of faucets, such as our stainless steel corrugated water hose Eco-Flex Water Mix.

- 1/2″ (12.5 mm): The most common size for connecting most household appliances and plumbing, such as boilers, columns, mixers, water heaters. Our company offers several solutions for these purposes: water hoses Eco-Flex Water Standard and Eco-Flex Water Super.

- 3/4″ (19 mm): For connecting washing machines, shower cabins, bathtubs, where a larger volume of water is required. This diameter can also be used in heating systems to connect radiators and convectors. Using the hoses Eco-Flex Water Heat and Eco-Flex Water Convector, you can make reliable distribution in any heating system in the house. The first of these hoses has insulation to minimize heat loss to the environment, and the second can be used to connect underfloor convectors in limited space.

- 1″ (25.4 mm): Heavier and less flexible than hoses of smaller diameter. Hoses of this diameter are used where a very large flow of water is required. This can be water supply for irrigation of large areas, connection to powerful pumps, use in construction work, in heating systems, for pumping water. It can also be installed to connect water supply to bathrooms, gas columns, water filters and other devices where high throughput is important.

- 1 1/4″ (31.8 mm) and 1 1/2″ (38 mm): These diameters are used mainly for specialized tasks where maximum water flow is required, for example, in industry, construction, for pumping large volumes of liquids.

- 2″ (50.8 mm): Hoses of this diameter are used in industry, for systems with maximum water flow.

The correct choice of water hose diameter will ensure optimal operation of your system, save time and resources, and extend the service life of both the hose itself and the connected equipment.

Why choose Eco-Flex flexible water hoses?

Advantages of water hoses from Eco-Flex:

- A wide range of water hoses of different diameters.

- High-quality materials – stainless steel is resistant to wear, temperature changes and pressure.

- Warranty from 5 years, service life can reach 15 years or more.

- Professional consultation – we will help you to choose the optimal solution for your task.

View our catalog and choose the hose that best suits your needs!

Need help with selection? Contact our consultants!