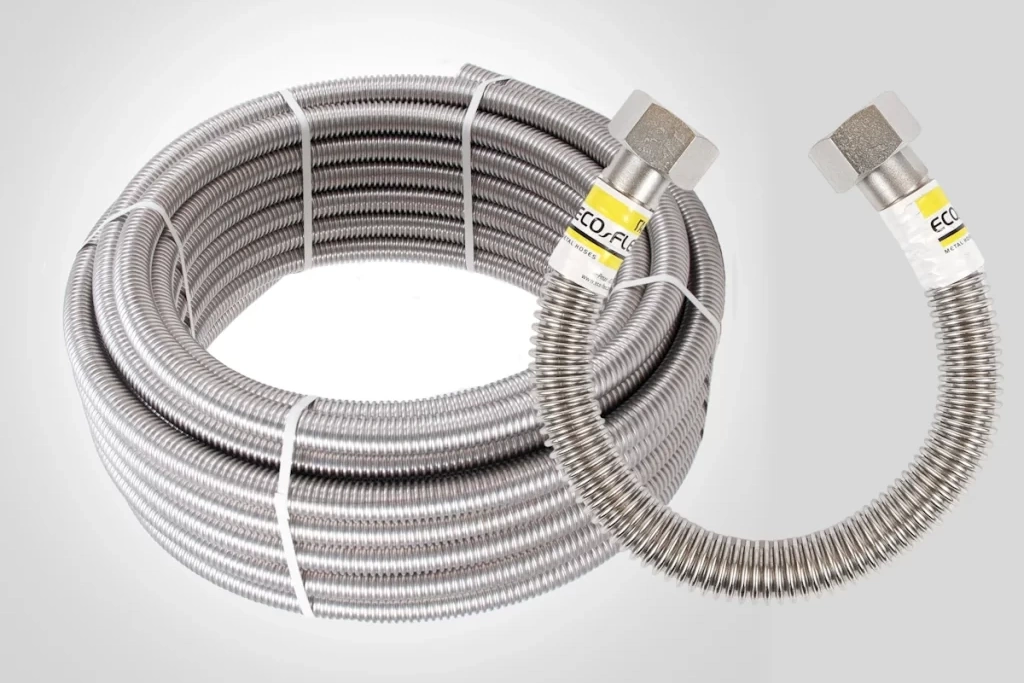

Stainless steel hose is a flexible pipe used to transport gases, liquids and steam under high pressure, temperature fluctuations and vibrations. Due to its design, it combines the strength of metal and the flexibility of a hose. Let’s take a closer look at what a hose consists of and how each of its elements works.

What is stainless steel metal hose?

A metal hose is a flexible tube made of stainless steel that provides tightness, mechanical strength, and durability of the connection. It is used in gas systems, heating, water supply, industrial installations, boiler rooms, and manufacturing.

The main structural elements of a metal hose

1. Corrugated tube (bellows)

This is the part of the metal hose that is directly connected with the working environment.

Corrugation functions:

- provides flexibility and the ability to bend;

- compensates for temperature expansion;

- withstands internal pressure.

The corrugation is made of stainless steel (most often AISI 304 or AISI 316) by corrugating a thin-walled pipe.

2. Fittings and end connections

Fittings are installed at the ends of the metal hose, which provide connection to equipment or pipelines.

Connection types:

- threaded (nut, fitting);

- flanged;

- welded;

- quick-release.

Fittings are made of stainless or carbon steel, as well as brass – depending on the operating conditions. After equipping with a fitting, the metal hose can be called a hose.

3. Sealing elements (if necessary)

Some designs use additional seals made of biconite or Teflon (PTFE) to improve the tightness of the connections.

4. Stainless steel braid (if needed)

The braid is an outer protective layer made in the form of a metal mesh.

Purpose of the braid:

- protects the corrugation from mechanical damage;

- limits the elongation of the metal hose under pressure;

- increases resistance to tearing.

Industrial metal hoses can use single or double braiding depending on the operating pressure.

5. Insulation (if necessary)

The PVC insulating layer acts as additional protection against corrosion and damage, and allows you to easily clean the hose or metal sleeve from dirt and dust.

How a metal hose works

The working principle of the metal hose is based on the combination of the flexibility of the corrugated tube and the rigidity of the braid. The corrugation allows the metal hose to bend and compensate for equipment movements, while the braid prevents excessive expansion under pressure.

Due to this design of metal hoses:

- does not collapse from vibrations;

- maintains tightness during temperature changes;

- works under high pressure conditions without deformation.

Advantages of stainless steel hoses

- high corrosion resistance;

- long service life;

- resistance to pressure and temperatures;

- universality of application;

- safety when working with gas and aggressive environments.

The structure of the stainless steel metal hose is thought out down to the smallest detail: each element performs its important function. This makes the metal hose an effective and safe solution for domestic and industrial systems.